Have you ever noticed that tiedown straps are almost always made with nylon webbing? Major brands like Rollercam love the stuff. But so do makers of off-brand tiedown straps. There are good reasons for this. Nylon webbing is an ideal material for making durable, long-lasting straps.

It works so well that manufacturers use it for all sorts of applications. It’s not just for tiedowns. Nylon webbing is ideal for backpack straps, musical instruments straps, purses, handbags, and so much more.

The Rollercam people say there are five things that make nylon webbing ideal for their cam buckle straps:

1. It Has a High Tensile Strength

Tensile strength is important when you are looking to secure loads for transit. Tensile strength is a measure of the amount of load a material can handle before it reaches breaking point. The higher the tensile strength, the stronger the material.

Nylon webbing’s advantage here is its tensile strength in relation to its weight and rigidity. Nylon webbing is lightweight. It is also flexible. These two properties allow manufacturers to produce straps that do not weigh a lot but are flexible enough to accommodate loads of virtually any size and shape.

2. It Resists Abrasion

Nylon webbing is an abrasion resistant material. This means it holds up very well even in situations where there is a lot of friction between strap and load. Unlike rope, friction doesn’t bother nylon webbing for the most part. However, the material does have one critical flaw: it can be cut very easily. That’s why experts recommend using edge protectors so that tiedown straps never make direct contact with sharp edges.

3. It Handles Water Well

Next up, nylon webbing handles water extremely well. Unlike some other materials, it does not easily absorb water. So even if it does get wet, it doesn’t stay wet for long. Water evaporates very quickly, thereby reducing the chances that tiedown straps will break out in mold and mildew.

Water resistance is a big plus when you are transporting loads on open trailers. You never have to worry about the straps being any less secure when they get wet. Wet straps work just as effectively as dry ones.

4. Little Maintenance Is Required

Nylon webbing doesn’t require a whole lot of maintenance. If it gets dirty and you really want to clean it, soapy water will usually do the trick. There isn’t much else to maintenance except taking care of the buckles. As for the straps, they are pretty much good to go as long as they aren’t frayed or cut.

There is one caveat here: nylon webbing doesn’t play well with some chemicals. When loads involve chemicals that could damage webbing material, another tiedown choice is necessary.

5. Nylon Webbing Is Versatile

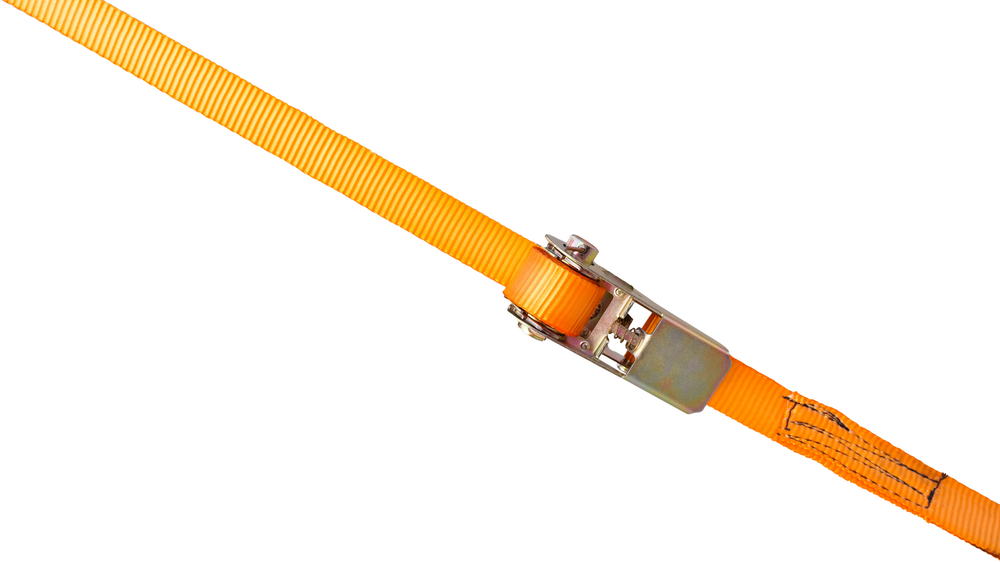

Nylon webbing is versatile enough that manufacturers can make a variety of different tiedown straps with it. The tie down straps straps from Rollercam.com are considered cam straps because they utilize a cam buckle to secure the strap material in place.

A manufacturer looking to make heavy-duty tiedowns for flatbed truckers could utilize nylon webbing just as easily for their ratchet straps. The webbing does the same job. The only difference is that the strap utilizes a ratchet instead of a cam buckle.

Tiedowns can be made using all sorts of materials ranging from canvas to rubber to hemp. But at the end of the day, no material beats nylon webbing. Tiedown straps made with nylon webbing are tough, flexible, lightweight, and versatile. They are suitable for nearly any application that involves securing a load for transport. Hands down, they are the best.

Using SQL for Bayesian Inference: Building Probabilistic Models with Data

Using SQL for Bayesian Inference: Building Probabilistic Models with Data  Why do people love the surprises in online slot games?

Why do people love the surprises in online slot games?  Can shockwave for ED help men with high cholesterol?

Can shockwave for ED help men with high cholesterol?  Feeding Sheep Through the Seasons: Changing diets for summer and winter

Feeding Sheep Through the Seasons: Changing diets for summer and winter  Role of CBD Vape Pens in Natural Pain Relief?

Role of CBD Vape Pens in Natural Pain Relief?  Simple Steps to Prevent Burnout Before It Takes a Toll

Simple Steps to Prevent Burnout Before It Takes a Toll  Why Low-Acid Organic Coffee is the Perfect Choice for Sensitive Stomachs?

Why Low-Acid Organic Coffee is the Perfect Choice for Sensitive Stomachs?  Which Ayurvedic Medicine is the Best Tablet for Piles?

Which Ayurvedic Medicine is the Best Tablet for Piles?  Discover the Latest Hits on Zee5: Must-Watch Movies and Series

Discover the Latest Hits on Zee5: Must-Watch Movies and Series